|

|

The

Purchase, Care and Feeding of a Home Wine Storage Unit -

Nov

3, 1999 -

A

little background: For years I've kept my wine in my home,

rather than renting a storage locker. I usually created a "cellar"

in the house by slightly remolding a hall closet, adding racks

and bins to the walls (closet 1, closet

2). Since these were less-than-ideal conditions for wine storage,

I always knew that one day I'd need/want to put my wine into a

rental locker or buy a wine storage unit for home. Moving our

residence was the motivation to actually do something about it.

While in the process of moving, I decided to put my bottles into

a storage locker (Wine Cellar Club)

for safe keeping, while I made a final decision.

Define

Your Needs - Pick Your Options - Watch Your Step

Meanwhile,

I researched the available brands of home storage units on the

market: Vinotheque, Vinotemp, Le Cache, Eurocave, etc., and decided

that since the unit would need to go in the garage, a high-end

piece of cabinetry wasn't necessary. After pricing the available

units, I determined that Vinotemp had the best price-per-bottle

ratio. Next, I needed to decide what size unit to get.

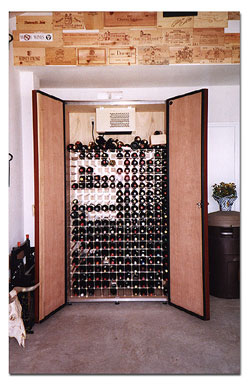

The

size of my wine collection has remained fairly constant at around

360 bottles or so. But, concerned about under estimating my needs

and buying something too small, I finally selected a Vinotemp

600-E. The unit came with black metal racking, 19 rows with 14

slots each row. Since the bottles store two-deep, I would have

a 532 bottle storage capacity in the individual racks, along with

additional "open" storage on the upper rack for magnums and such.

I priced the unit at the local wine stores versus the factory,

and found the wine stores to be the least expensive (I presume

this is because the factory doesn't want to compete with its distributors).

At additional cost, I swapped out the black metal racking for

redwood racking, added a heavy-duty compressor and a door lock,

and had them finish the mahogany exterior of the unit.

Unfortunately,

the racking I received was not in fact "redwood." Rather,

it was something called "California wood racking," a

matrix of wood and aluminum. I was disappointed - largely for

asthetic reasons, since I thought I was completely eliminating

metal for wood. But I was also disappointed because, after researching

the racking issue a great deal, it turned out that the full redwood

racking was apparently only available to those who ordered directly

from the factory. So, the factory had two racking options available,

while the distributors only have the one. Adding insult to injury,

the distributors are charged the "redwood" price for

the less expensive racking.

|

Placement

Can Be Crucial

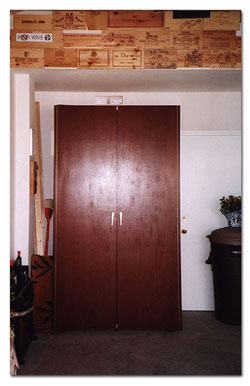

After

about six months in cold storage at a local wine locker

place, I brought everything back to the house and started

stocking the newly acquired Vinotemp

600-E. Of course, this was not without one small problem.

I

had planned to put the unit in a corner of my garage, and

even had the electrical outlet converted from a GFI circuit

to a regular circuit in order to reduce the risk of an electrical

shutoff. I positioned the Vinotemp exactly where I wanted

it, glued some plastic letters and numbers on the ends of

the racking as an indexing system, and then went to town

filling the holes with bottles. I started with the right

side, since the doors overlap each other and the right-hand

door needs to be opened first. After I'd finished loading

the right side, I pulled the upper and lower locking pins

on the left door, opened and swung it around to start loading

the left side. That's when I realized I'd overlooked something

... something fairly important.

As

it happens, the door(s) of the unit need to swing out nearly

180-degrees for complete loading. Otherwise, you

can't get bottles into the outside columns between the cabinet

wall and the racking. But unfortunately, the left-hand door

would not swing out far enough without hitting the wall,

meaning the cabinet needed to be moved about six more inches

to the right. (I should have remembered that old model-building

instruction: "Make sure parts fit BEFORE applying

glue.") |

|

|

|

|

Now

I was facing a really unpleasant decision -- just forget

about using the far left column, or move the unit over a

bit to the right so I could open the door. Well, it wasn't

going to be possible to push or pull this partially-loaded

monster the required distance. And, I certainly wasn't willing

to abandon the potential storage space for 40 bottles of

wine. So, I ended up unloading nearly the entire 20 cases

from the right side of the unit, before pushing the Vinotemp

several inches to the right. Then I got the privilege of

reloading all that wine. Of course, it's not just the unloading

and re-loading that's difficult -- I'm also keeping an inventory.

So, all of the bottles need to go back into the correct

slots. Then, since the concrete slab of the garage is a

bit irregular, I needed to re-adjust the leg levelers to

balance the doors.

One

other thing I discovered: the depth of the unit and the

dimensions of the racking are not conducive to many of today's

wine bottle sizes. Frequently, taller bottles will not fit

end-to-end in the two-deep slots and still allow the door

to close. Other times, the bottle will be too fat, and have

to be stored in the upper open area. I'm sure there may

have been some custom-sized racking options available from

Vinotemp which would have helped solve the fat-bottle problem.

But, there wasn't anything I could do about the depth problem,

other than to alternate bottles of various heights into

each of the slots, to be sure that everything cleared the doors.

Another small thing. Because of the overlapping door design, the door jamb of the left-hand door protrudes inward (compensating for the cutaway portion on the outside that receives the overlapping right-hand door). This effectively reduces even further the size of bottles that will fit into that particular column.

Finally

finished, I stood back and admired the cellar. What a thing

of beauty; I've got to get more wine, I'm sure I must have

said to myself.

|

|

March

15, 2000 -

Something

interesting was beginning to develop. Since the doors of

the unit overlap, I tended to favor loading the unit primarily

on the right side, then secondarily on the left side. I

also deferred loading bottles into the far left-hand column,

just because it was the tightest angle at inserting/removing

bottles. Well, to my dismay the racking and contents in

the bottom 1/3 of the unit were beginning to shift to the

left (slightly evident in the picture above). Now obvious,

was the fact that all that downward weight on the racking

caused it to shift to the unbalanced side. Well, I figured

I could just move some bottles over to fill the left-hand

column and balance the load - no problem. Nope! The shifting

had actually squeezed down the slot size, so now I wasn't

able to insert any bottles. So, guess what? Yep, yet another

unscheduled unloading of cases and cases of wine. Interestingly,

with most of the bottles from the upper rows removed, the

racking actually sprang back to its original shape, and

the reloading began. Sigh, seat-of-the-pants engineering.

October

25, 2000 -

It

appears that the left-hand door is getting harder to close

tightly -- at least enough so that the locking pins at the

top and bottom of the door can be slid into the bracket

holes. Also, the right-hand door doesn't seem to be adjusted

correctly, being a little lower at the bottom where the

two doors meet. Because of this, the seal is leaking a little

air (which I can feel with my hand, when the compressor

is running). This all seems kind of weird, since I really

haven't done anything to the unit since March. I'm guessing

that the house/slab is settling a bit, thus throwing off

the alignment of the unit. So, I re-adjusted the levelers

again, and presto, everything was back in balance. |

| |

|

Things

get Interesting - See Part

2

|

|

|