|

|

The

Purchase, Care and Feeding of a Home Wine Storage Unit -

Part

2

March

23, 2002 -

Hey,

What's That Noise?

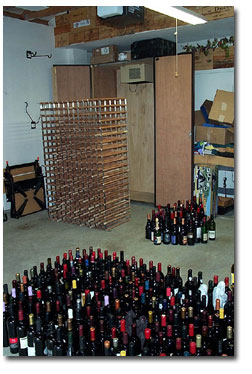

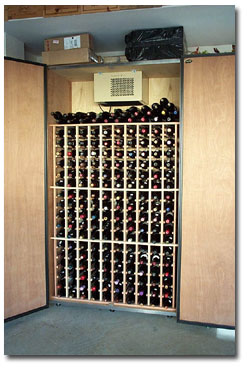

Things

had been going very good. My inventory was now up to 465 bottles,

still nowhere near the 560 rated capacity of the unit. This evening

I opened the doors and grabbed a couple of bottles for dinner.

While I was standing there for a moment admiring the symmetry

of the colored foil capsules, I started to hear a creak, then

a crack, and then a groan. Something was happening, and it sure

didn't seem like good thing.

|

I

watched

in horror as the 2nd row from the bottom shifted to the

left, and the weight of the upper rows started to collapse

the three bottom rows into an accordion shape. I stood like

a deer in the headlights for a moment - wondering if bottles

on the bottom would start getting crushed. Then, full anxiety

hit. How was I going to get the impending sea of wine out

of my garage, I thought.

|

|

|

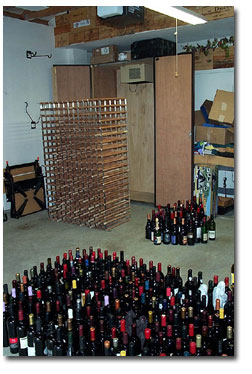

Then,

no more noises - nothing else moved. I reacted quickly.

I grabbed a small step stool and started to pull bottles

off the upper shelf. Then, I pulled out all of the bottles

from each of the rows, placing them at strategic positions

on the floor (don't forget, with an inventory-based on

location, I had to put them back into just the right slots

- that is, assuming I'd still have slots to put them into

when this is all over). Meanwhile, I was surveying the

damage as I went, trying to mentally concoct a fix - temporary

or otherwise - since I wasn't going to get a replacement

rack anytime soon.

One-hour

and 465 bottles later, I was able to assess the damage.

Diagnosis: despite the evenly distributed weight, the

stress on the aluminum uprights caused them to bend and

finally buckle, with the 2nd and 3rd rows shifting to

the left, and the 4th row listing to the right. This misalignment

caused several of the wood runners in the lower few rows

to split at the grooved points where the horizontal and

vertical aluminum struts intersect, allowing even further

movement.

|

|

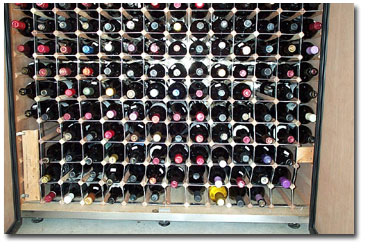

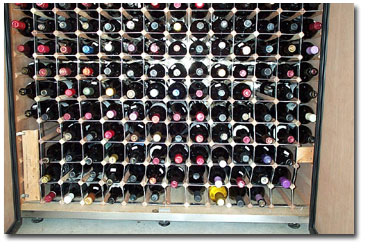

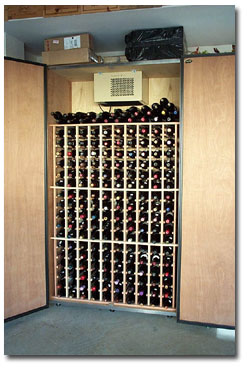

The

Design

(This

racking design places the unit in the center of the cabinet

from left-to-right, and attaches it to the back wall with

4 screws. At the front of the cabinet, 3 of the horizontal

aluminum crosspieces are elongated, and fit into slotted

pieces on the side walls, keeping the rack equally positioned

between the side walls. The rack itself has 12 bottle slots

horizontally, but uses its outside runners in conjunction

with rails mounted to the inside of the cabinet walls to

support an additional row of bottles on each side, for a

total of 14 bottles wide. While this certainly maximizes

the bottle capacity, iit also makes a maintaining a balanced

load very important.

Notice

that except for the 3 struts, the outer row on either side

does not have horizontal pieces of aluminum steadying or

supporting it. Therefore, in order to balance the

load, it's important to equalize the weight across the

rack. The downward pressure from the weight of the bottles

is therefore absorbed by the vertical struts, while the

3 horizontal struts maintain the vertical angle, and the

unit's integrity. Finally, there is a matrix of aluminum

struts framing the entire back of the rack. Although this

maintains rigidity in the back of the rack, it does nothing

for the front of the rack. Therefore, any collapse will

normally take place at the front of the unit, effectively

tipping everything forward.)

A

Temporary Fix

With

all of the bottles out of the rack, I tried to bend the

bottom rows back into shape. But, to no avail. There just

wasn't enough room to get the leverage needed to push or

pull the rows back into shape. So, I pulled out the 4 screws

that held the rack to the back of the cabinet, and snaked

the rack out so I could give it some first aid. Turning

it on its side, I succeeded in pushing the bent section

back a little more into its proper shape. It occured to

me at this point that it might be possible to turn the rack

upside-down when putting it back into the cabinet. I thought

maybe having the un-damaged section on the bottom would

give the unit greater strength. Unfortunately, this wouldn't

work, since the aluminum struts wouldn't match-up with the

grooved side rails on the cabinet walls.

|

|

|

|

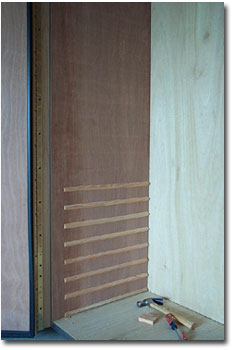

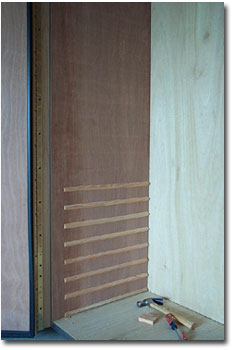

After

bending the rows back into shape as much as I could, I put

the rack back into the cabinet and tried to come up with

some quick fix to keep the thing from collapsing again or

bending even more. My solution was less than illustrious,

but it did seem to work.

I

used some scrap wood to make a couple of shims - one shim

to keep the left side from buckling further in that direction,

and another shim to counter the pressure that would be created

on the right side. There really wasn't much I could do about

the splintered wood runners, so some of my storage was lost.

But, I viewed this whole thing as a temporary fix, anyway.

Ultimately, I needed to make a call to Vinotemp to sort

this thing out.

|

|

What

Now?

So,

how's a thing like this happen? Well, I suspect that the

original "S-shaped" stress bend that I noticed

in the rack awhile back (see),

had probably caused some metal fatigue in the aluminum toward

the bottom of the rack, thus ultimately turning the "S"

bend into a "Z" bend. Looking into the warranty

issue on the unit, the Vinotemp limited warranty is 5-yrs

on the compressor, and 12-mos on the cabinetry. Anticipating

that they probably wouldn't cover this problem, I was prepared

to argue the point. However, I'm pleased to say that the

company stood behind their product, calling this as an unfortunate

anomaly. When I questioned the integrity of the rack design,

they replied that although they couldn't say they'd never

seen this happen, there is nothing wrong with the design

itself.

They

offered me a new replacement rack of the same design; I

would only have to pay for shipping. I explained to them

I was still worried about the design - especially the integrity

of the aluminum uprights, and told them I wasn't sure I

wanted to take a chance on this happening again. They said

they obviously couldn't guarantee that it wouldn't happen

again, but said the rack design was sound, and it was very

unlikely. I still wasn't convinced, and expressed a desire

to upgrade to the all-redwood design that I'd wanted initially.

They agreed to do so for a nominal charge. They said they

needed to build the rack, and I should expect a call in

about 7-10 days.

On

the up side, I was getting a nice new all-wood rack. On

the down side, this new racking will cut my storage capacity

about 25% (the redwood's thicker, and the rack doesn't utilize

the inside-wall rails to hold the bottles - which means

that I'd also need to remove all of the side rails before

sliding in the new rack). On the other hand, I thought the

redwood would be more aesthetically pleasing; plus, the

bottle slots are slightly larger, so all of the bigger Pinot

and Syrah bottles will now fit into the slots. So, the only

real question became, what would I do with the 3-4 cases

of wine that won't fit in the cellar? Yes, I know - that

does sound like a good excuse for a party.

|

April

13, 2002 -

New

Rack Installation

|

Vinotemp

had called earlier in the week to say the new rack was ready

for pickup. First step was to get all of the bottles out

of the rack, and remove the old rack from the cabinet (yep

- deja vu, all over again). My wife and I managed to get

all the bottles out and lined up on the garage floor. Then

we yanked out the old rack. After that, the bottle supports

on each side wall had to be removed. This proved easier

than I'd thought, because the supports had been stapled

to the sides through the thin mahogany and into the foam

core. Only one support on each side (at the mid-line) gave

me any problems, and that was because the staples probably

went through some adhesive between the wall and the foam

inside the wall.

|

My

fellow wine-road traveller, Michael, had volunteered himself

and his van, so we headed up the 35 miles or so to Rancho

Dominguez to pick up the new rack. On returning, we got

the new rack into the cabinet without a hitch, then proceeded

to load all of the bottles - well, almost all the bottles.

The old racking system had 14x20 bottles slots, for a total

of 560 bottles. The new rack has 10x17 slots, for a 340

bottle total. To that, you can add another 40-50 bottles

on top (probably more, if you're brave), making a total

of 390 bottles. As you can see, the upper reaches of the

cabinet are under-utilized - unless you really stack those

bottles up there. So, one of my future projects is to build

some additional smaller racks to go on each side of the

cooler. They do sell small racks for this purpose, but they're

$80 each.

|

|

Michael

and I had decided to re-inventory all the bottles while

loading the rack. Inventorying is kind of an amusing process

in itself. Amazingly, we found bottles that I'd written

off as lost, when I couldn't them find in previous attempts.

And, there were also a few corrections in order - for instance,

I had the vintage recorded as one thing, but it turned out

to be another (that Michael, trust him to find the

mistakes).

I

was delighted to see that nearly every size of bottle fit

easily into the slots of the new rack - with room to spare!

Gone was the previous problem of worrying about the bottle

thickness - this full-redwood rack has nice large openings.

But, still present was the hassle created by various bottle

heights. As mentioned, many of the newer Cal Cabs are elongated

(thus taller) in shape, making them look very elegant, but

also making them very difficult to place end-to-end in a

conventional rack (the rack is 2-bottles deep). Also, Cal-Itals

like Barbera and Sangiovese have very long necks, and often

exceed the unit's depth if placed end-to-end into the same

bottle slot.

Much

better! The whole thing looks very nice. And, as a little

bonus, I can now get to the 1st column of bottles without

having to take down the bicycles to get the door open wider.

Yes, it has a lot less storage. But, given the sturdiness

and the look of solid wood, I'm real happy the old rack

took a dive. Speaking of which, the Vinotemp factory didn't

want the old unit back. So, right now it's temporarily in

the back yard until I see if some parts are salvagable to

use for additional racking - or until the wife tells me

that either the rack goes, or....

|

|

| Beginnings

- Back to Part 1 |

|

|

|